Since its establishment in 2009, the company has focused on the research and development of polyamide engineering plastics modification technology, and the product application field initially focused on the field of low-voltage electrical appliances. After forming a strong competitive advantage in the field of low-voltage electrical appliances, the company has expanded to automotive, heat dissipation and other fields on this basis. At the same time, in order to meet the needs of customers' overall product solutions, the company has increased the product categories of PBT, PET and PPS. At present, it has formed a product structure based on modified PA, supplemented by other modified engineering materials and taking the overall solution as the core goal. The company's products can be divided into modified PA6 series, modified PA66 series, modified high temperature nylon series and other modified engineering plastics series (mainly PBT, PET), mainly used in low-voltage electrical core parts, automotive engines and surrounding high heat resistance, alcohol-resistant functional parts to plastic instead of steel and other fields, LED, communication, security and other cooling systems to plastic instead of aluminum.

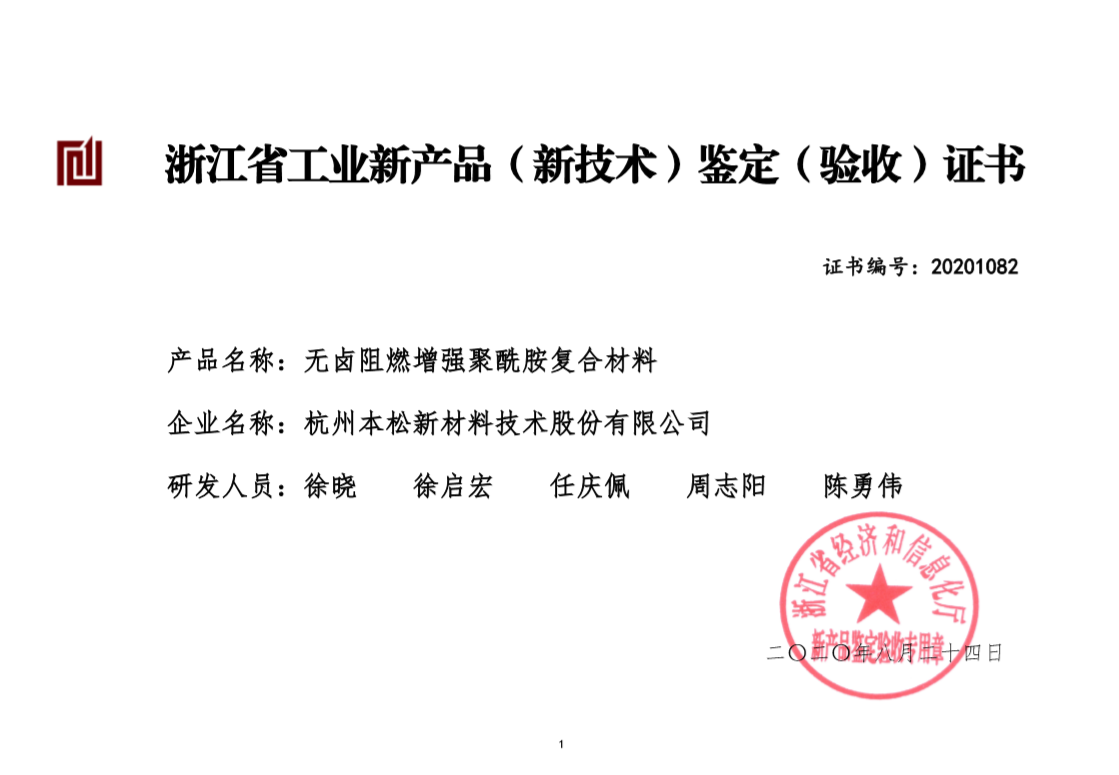

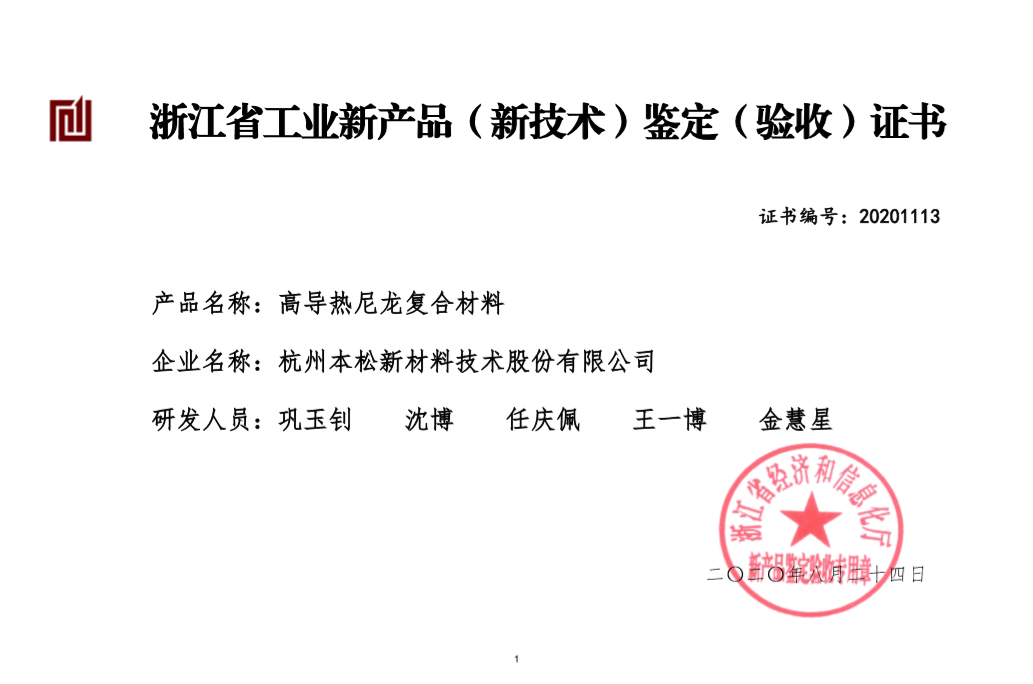

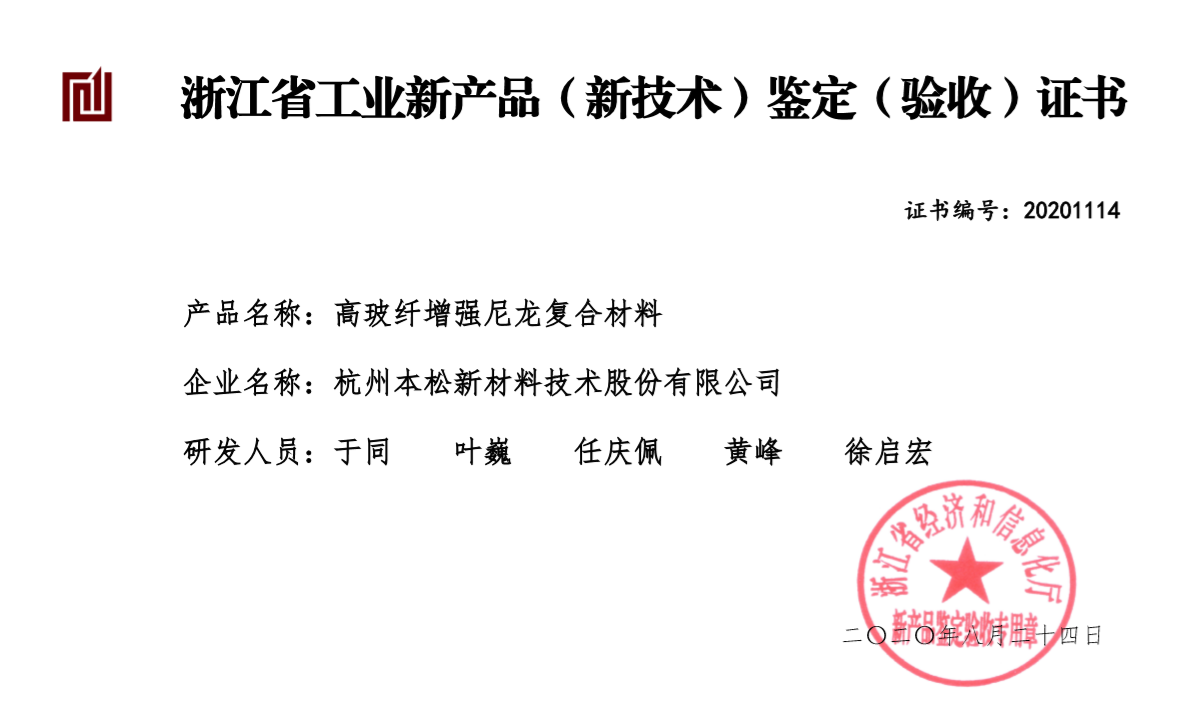

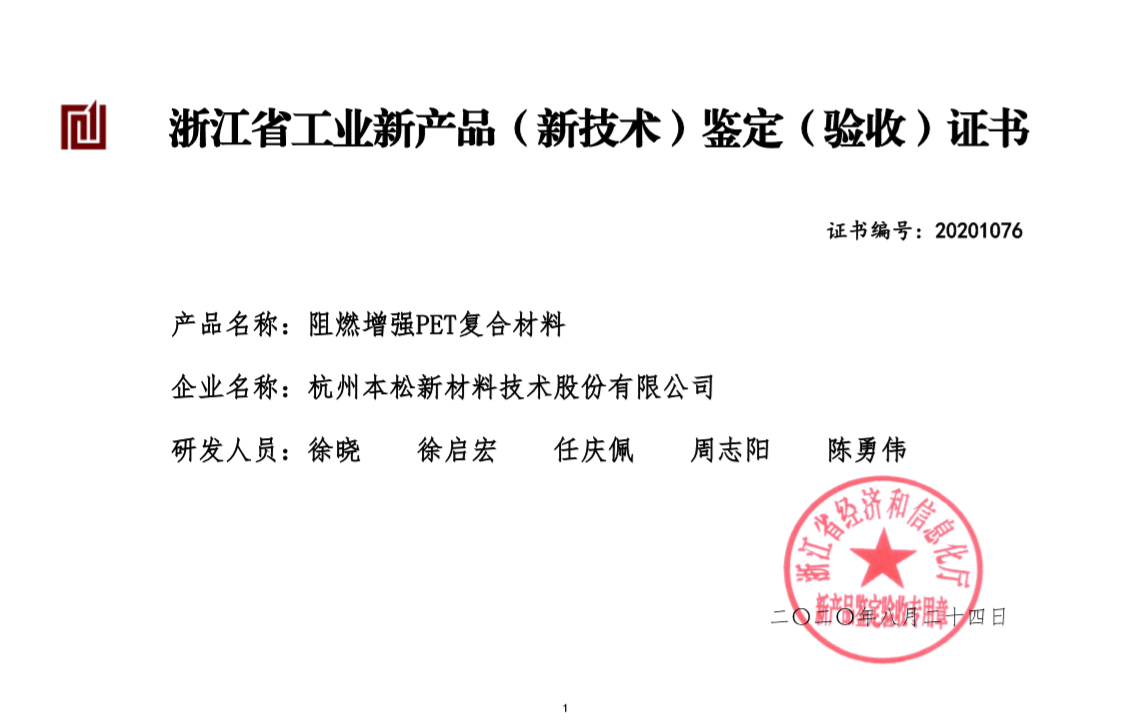

The company's products have excellent performance and stable quality, and have won wide recognition from customers. According to the statistics of the China Plastics Processing Industry Association, in 2019 and 2020, the halogen-free flame retardant reinforced polyamide composite materials produced by the company ranked first in the domestic market share in the field of low-voltage electrical appliance applications. On August 15, 2020, the expert appraisal meeting organized by the Zhejiang Provincial Technology Brokers Association under the Zhejiang Provincial Science and Technology Department determined that the three types of products of the company, "nitrogen and phosphorus flame retardant reinforced polyamide composite material", "low cost and high performance nitrogen flame retardant polyamide composite material" and "low phosphine release red phosphorus flame retardant polyamide composite material", have reached the international advanced level. On August 24, 2020, the "Zhejiang Province Industrial New Product Identification Certificate" issued by the Zhejiang Provincial Department of Economy and Information Technology respectively identified that the company's "high thermal conductivity nylon composite material" applied in the field of LED heat dissipation has reached the leading level in China. The "flame retardant reinforced PET composite material" and "high glass fiber reinforced nylon composite material" applied to automotive engines and peripheral parts have reached the domestic leading and domestic advanced level respectively.

On November 4, 2020 and January 29, 2021, the Expert Appraisal Committee of the China Light Industry Federation identified the company as having reached the international advanced level of "flame retardant enhanced high temperature resistant nylon composite material" and "industrialization and application technology of high thermal conductivity nylon matrix composite material".

The company has won the honors of Zhejiang Province invisible champion enterprise, state-level specialized special new small giant enterprise supported by suggestions, national high-tech enterprise, provincial high-tech enterprise research and development center, provincial key enterprise Research Institute, and district mu yield hero. Bosom New Material iot smart factory won the Hangzhou factory iot, industrial iot demonstration project, Hangzhou and Wuhu testing and analysis centers have passed the accreditation of China National Accreditation Service for Conformity Assessment (CNAS) laboratory, the existing 15 large laboratories, testing equipment more than 170 sets, Can detect mechanics, heat, flame retardant, electrical, chemical, aging and other items.

The introduction of fine management began when the company was established. At the beginning of the establishment of the financial strength is still limited period, the company hired the British Navelg management consulting company to guide the company to implement lean production. Since then, the company has introduced the Japanese 6S management method, and the company's fine management has been further deepened. Passed the ISO 9001 Quality management system, IATF16949 automotive quality management system, ISO 14001 environmental management system, ISO 45001 Occupational Health and safety management system, intellectual property management system, GRS , ISCC certification. Bosom adhere to the advanced technology and the spirit of struggle, to provide customers with stable quality, continuous reduction of system cost, the most cost-effective competitive solutions.

浙公网安备33011002011562号

浙公网安备33011002011562号 Mail

Mail Office System

Office System